Epoxy Garage Floors in Ogden, Utah

Epoxy garage floors are extremely popular, due to their aesthetic appeal, ease of maintenance, and protective properties. They’re also very well known for how long they take to cure and the fact that installation takes several days. Epoxy garage floor coatings are similar to polyaspartic floor coatings, though the latter is more flexible and durable.

Concrete Coating in One Day!

-

7 am

Preparation & Grinding -

9 am

Concrete Restoration -

10 am

Base Coat & Chip Application -

12 pm

Setup Time -

1 pm

Scraping -

2 pm

Top Coat

What is Epoxy?

Epoxy is a type of resin that can be combined with a hardener in order to make strong adhesives, primers, and flooring coatings. Epoxy results in a gorgeous floor that can be customized with its range of colors and designs. It can be combined with other products in order to give it a grippy texture to prevent slipping.

How are Epoxy Garage Floors Applied?

- Before you can apply any coating, you’ll need to prep your garage floor by removing any current coating, as these would react negatively with the epoxy and result in a lower quality floor.

- You’ll then need to clean the floor thoroughly, removing any greasy or oily residue. You may consider acid-washing the concrete for a really deep clean.

- If there’s any solid residue, like rubber, you’ll need to scrub the floor until it’s clear.

- Then, you’ll use the etching product that comes with your epoxy kit, a scrub, and follow the given instructions. Be sure to let the floor dry completely before attempting to apply the floor coating.

The Application Process

- Make sure you have enough for 2 coats of epoxy.

- Wear PPE (personal protective equipment) like a mask for your nose and mouth, lenses for your eyes, and boots to protect you against the health hazards of solvent-based epoxy.

- Apply an epoxy primer that is compatible before you apply the first coating. Let it dry completely. You can use a nap roller with a handle to apply this. The primer will make the floor coating more durable.

- Follow the instructions to mix the epoxy and then apply the first coat. Wait at least one day and one night for it to dry completely.

- If the first coat dries without any uneven patches or cracking, then you can apply the second coating. If it did crack, you can use an epoxy filler to cover them and wait 12 hours for it to dry.

- After applying the second coating, wait a day and a night for it to dry completely.

Comparing Epoxy to Concrete Polishing

Epoxy garage floors have their pros and cons, the same as anything else. When choosing the right flooring for your garage floors, you’ll want to know the best option for you. Epoxy and concrete polishing both have their strengths and weaknesses.

Epoxy isn’t immune to scratching or peeling off and requires special products in order to bring it back to its original shine. However, it is skid-resistant and better suited to water resistance than concrete polished. It can also hold up against chemicals.

Concrete polishing won’t scratch or come off like epoxy floors, and they’re easier to clean. Concrete can be destroyed by chemicals, suffering from stains or corrosion.

You can make a concrete epoxy combination in order to even out the imbalances between concrete and epoxy floors. Through adding two coats of epoxy onto a concrete floor, you can hide concrete imperfections and give your garage floor a facelift. The epoxy will need to be replaced every five years, otherwise it begins to lose its famed durability.

Your epoxy garage floor is more prone to grease stains, oil spills, chemical spills, and other damaging agents than any other part of your home. As such, applying an epoxy layer onto the concrete is the best move to make in order to protect it and increase its aesthetic appeal.

Advantages of Epoxy Garage Flooring

- Epoxy is less expensive than other floor coatings, since it can be applied on other floorings, and the existing floor doesn’t need to be removed before application.

- If installed correctly by trained specialists, epoxy provides protection from cracking and dirt and has reduced chances of peeling off.

- Epoxy reflects light well, which improves the safety of your garage through increased visibility.

- It comes in a wide range of colors so your floor can look just how you want it to.

- Epoxy is impact resistant, making it durable.

- Epoxy garage floors are smooth which makes cleaning them easy.

Disadvantages

- Epoxy is slippery, which can result in accidents and injuries when things spill.

- It isn’t easy to remove without damaging the floor, which leads to additional costs when you need to replace i

- Though epoxy has immunity to cracks, it needs to be replaced as soon as it begins to show wear and tear.

- Epoxy has strong fumes and VOCs.

- Its durability is very dependent on the expertise of the installer.

- It has a very involved application process. You can only apply a second layer after the first one has completely dried.

We Offer the Highest Quality Garage Floor Coating in the industry

-

Done in one day

We don’t waste your time and strive to complete all floor coating projects in one day. We know how inconvenient it is to have to stay off your floors, which is why we work hard and fast so you don’t have to wait longer than a day before you have your floors back.

-

Top Notch Service

We strive to provide the highest quality products, workmanship, and service to every one of our customers. We hire only the best employees who are polite and will respect you and your property as if it is their own. Contact us today!

-

Best Products

We only use the best products, materials, and equipment on the market to ensure your floor coatings last as long as possible and have high performance. You pay for quality when you choose to work with us, and we are confident that you will have an excellent experience.

-

We Give Back

We partner with you to give back to your favorite charities such as the Oxalosis & Hyperoxaluria Foundation, Wounded Warrior Project, and Best Friends Save Them All. Help yourself and others by working with us for all your garage floor coating needs

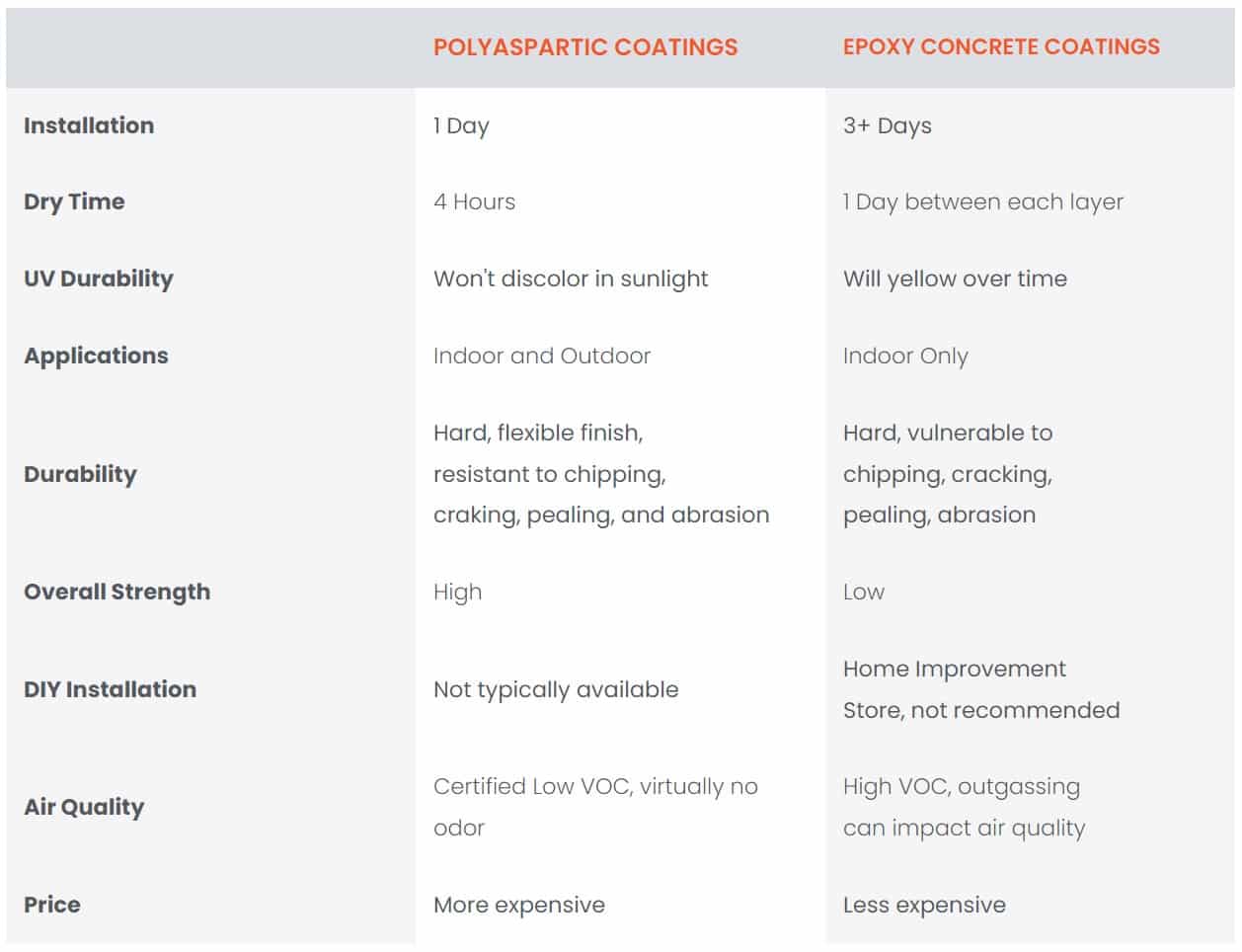

Polyaspartic Flooring: An Alternative to Epoxy Garage Floors

Polyaspartic floor coatings are among the most efficient on the market. They last longer, can withstand chemicals and weather impact, and don’t need an additive in order to do so. This type of flooring is more efficient compared to many other materials.

While epoxy garage floors fade with UV fades, polyaspartics are UV resistant. Polyaspartic cures with the day, making process of getting a floor coating far less time-consuming. If you’re applying a floor coating, you want the most durable and beautiful option – and polyaspartics are just that.

A Case for Polyaspartic Floors against Epoxy Flooring

Generally, both polyaspartic and epoxy floors are durable, aesthetically appealing, and protect your concrete from damages. However, polyaspartics are elastic, which means that they adjust to temperature changes easier without cracking. To learn more about polyaspartic floor coatings and why we prefer them over epoxy, contact us today!

Call us Today! 801-797-3663