Polyaspartic 1-Day Garage Floor Coatings

Polyaspartics and polyureas are two different kinds of floor coatings that are within the same family tree. They were developed in the 80’s by Bayer Material Science, one of the leading chemical companies in the world, and as such, have become one of the best concrete coatings available on the market today. These floor coatings are renowned for their rapid curing time, which makes professional application a must. If you try to apply Polyaspartic and polyurea floor coatings and you aren’t an expert, you could very easily ruin your floor, since they cure so fast. While epoxy coatings take 5-10 days to cure, Polyaspartic and polyurea coatings set so quickly that you can use your garage again within 24 hours after application.

Concrete Coating in One Day!

-

7 am

Preparation & Grinding -

9 am

Concrete Restoration -

10 am

Base Coat & Chip Application -

12 pm

Setup Time -

1 pm

Scraping -

2 pm

Top Coat

Polyaspartic: A More Durable Garage Floor Coating

Polyaspartic and polyurea are distinguished because although they come from the same family, they’re not the same. Polyaspartics are a kind of polyurea that has been modified to improve on the areas in which typical polyurea could use strengthening. While polyurea is not UV resistant, Polyaspartic is. They’re also extremely durable and a good option for outdoor application, however, they can get slippery when wet. This issue can be resolved with a grit additive that provides slip resistance, which we recommend if you’re having exterior surfaces coated. If you’re having your garage coated, you can likely get away without the additional grip.

Polyaspartic and polyurea coatings aren’t restricted to floor applications – they can also be applied to steps. Nor are they confined to concrete. You can have vertical and wooden surfaces, since these materials set and adhere so well. While wood can’t be warrantied, applying coatings to it will still help it last longer than paint.

Polyaspartics are six times stronger than epoxy floor coatings, which is a key factor to consider when deciding on the kind of floor coating you want for your project. If you’re coating a garage floor that needs to withstand a lot of vehicle traffic and impact, then a Polyaspartic coating is going to hold up much better than epoxy. While there is a difference in pricing between epoxy and Polyaspartic, it’s marginal. Polyaspartics are known for their stunning, customizable flake look from vinyl paint chips which creates subtle texture on the floors, making it less slippery and more resistant to scratching. When you use polyaspartics, your floor can look how you want, be it quartz, a solid color, or a more customized design. They can also be used for indoor applications, so you aren’t restricted to your garage and exterior surfaces when you choose polyaspartics.

When you want floor coatings for interior spaces, ultimately, whether or not you go with epoxy or Polyaspartic coatings comes down to the design. If you have concrete, it’ll need to be ground down with diamonds to strip off any previous coatings or staining and smooth the surface, for the best possible application of polyaspartics and polyureas. This process requires professional equipment, and for said equipment to be hooked to vacuumed, so that all the dust the process generates doesn’t leave a mess. When you work with us, you can rest assured there will be no clean up for you when we’re done!

We Offer the Highest Quality Garage Floor Coating in the industry

-

Lifetime Warranty

To ensure you are 100% satisfied with the finished project, we provide a lifetime warranty for all our coatings. We guarantee that you’ll have the floor of your dreams when we get done, but if you aren’t completely satisfied with our work then we won’t charge you.

-

Done in one day

We don’t waste your time and strive to complete all floor coating projects in one day. We know how inconvenient it is to have to stay off your floors, which is why we work hard and fast so you don’t have to wait longer than a day before you have your floors back.

-

Top Notch Service

We strive to provide the highest quality products, workmanship, and service to every one of our customers. We hire only the best employees who are polite and will respect you and your property as if it is their own. Contact us today!

-

Best Products

We only use the best products, materials, and equipment on the market to ensure your floor coatings last as long as possible and have high performance. You pay for quality when you choose to work with us, and we are confident that you will have an excellent experience.

Only the Best Materials: Polyaspartics

While polyureas and polyaspartics can have a smell and Volatile Organic Compounds (VOC’s), depending on the manufacturer, they’re still not as strong and don’t last as long as epoxy fumes do, although they can still last for a few days to over a week. High VOCs can cause eye and throat irritation, coughing, and headaches, which is why we teamed up with, RESINWERKS. RESINWERKS produces polyaspartics that have the lowest VOCs and solvents with the highest quality raw materials in the industry. 90% of their products don’t have an odor, and the remaining 10% have very minimal odor.

Applying Polyaspartic and polyurea floor coatings necessitates professional training and equipment. This isn’t a DIY job, because these products have a very limited working time and you need to have the precision required in order to do the prepping, application, and finishing within said time frame in order to achieve a beautiful finish. If you’re looking for floors that are both beautiful and functional, that will increase the value of your home while making it more damage resistant, these are the floors you want. Our expertly trained professionals will ensure that you get the floors of your dreams.

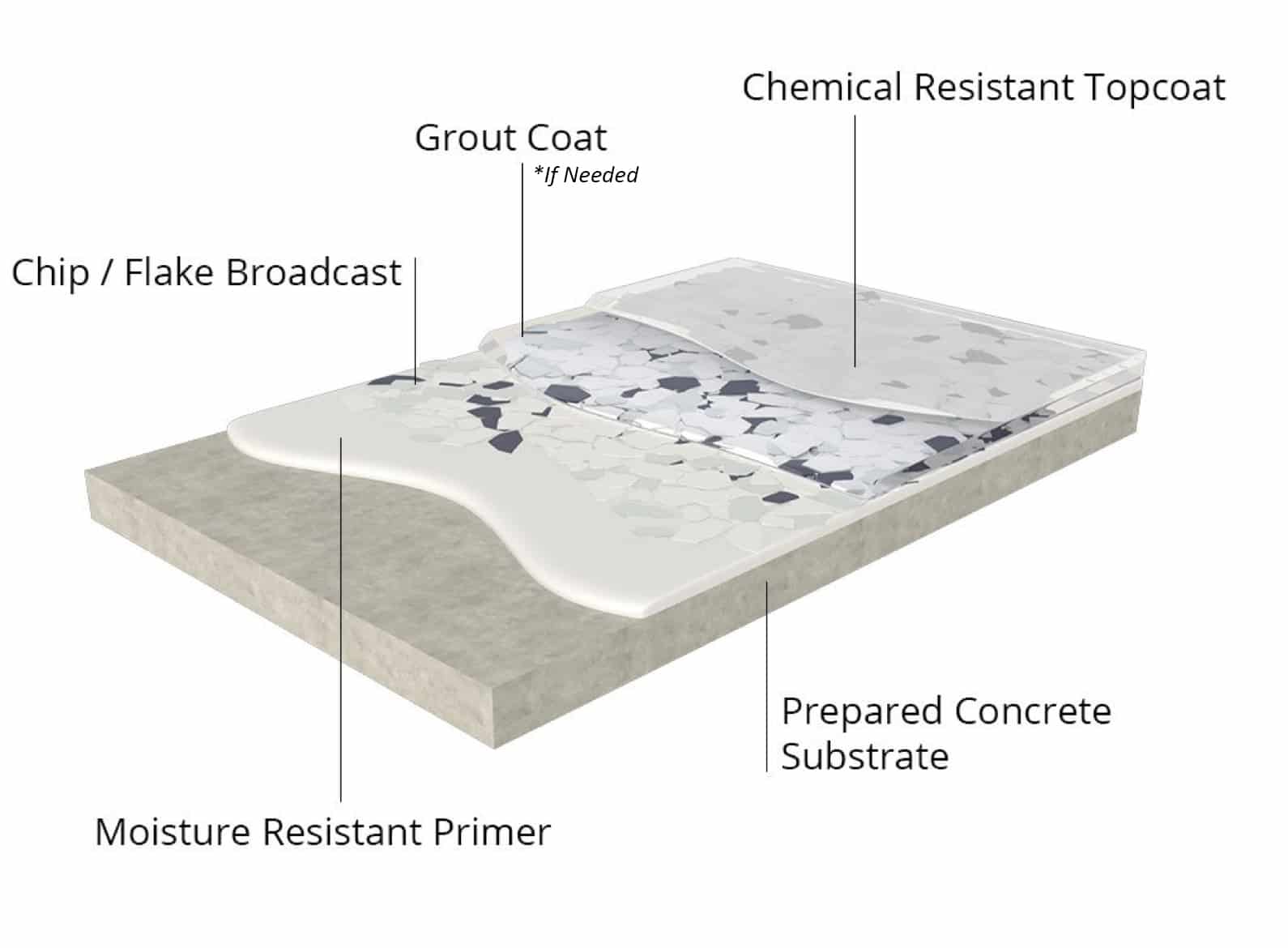

These flooring systems can be laid down in three separate ways. Polyaspartic systems entail a topcoat of Polyaspartic, and can use three different base coats: epoxy, polyurea, or Polyaspartic. While all three work, epoxy and polyurea aren’t as durable and won’t last as long as Polyaspartic.

While most companies use these products to save themselves money even though they end up costing you more in the long run with how much more maintenance they’ll need, we use premier polyaspartics for both our base and top coats. The last thing we want is for your coating to fade or discolor or not last as long as it should. If we feel that there are moisture issues within your concrete, we’ll use a vapor barrier epoxy for the base coat.

Client Testimonials

View More Testimonials